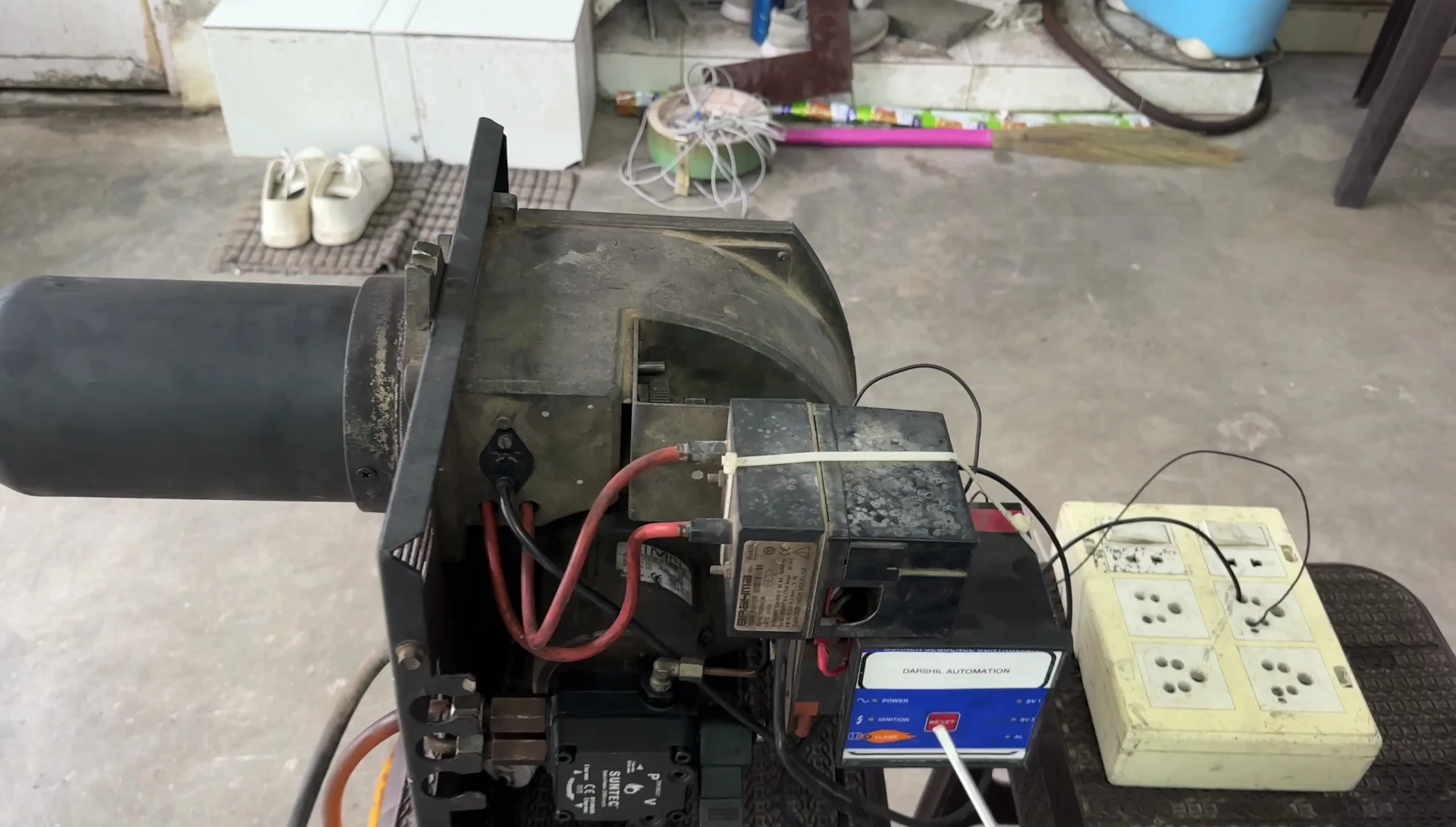

This comprehensive guide provides essential troubleshooting and maintenance information for oil and diesel burners. Proper upkeep of your burner is crucial for ensuring efficient operation, preventing costly repairs, and maximizing the lifespan of your system. We cover key components, including the nozzle, fuel pump, sequence controller, and wiring, providing step-by-step instructions for common maintenance tasks and troubleshooting potential problems. Understanding these procedures will empower you to perform routine checks and address minor issues before they escalate into major malfunctions.This guide emphasizes safety throughout, highlighting critical steps to take before undertaking any maintenance or repair work. Whether you're a homeowner or a professional technician, the information presented here will help you maintain the safe and efficient operation of your oil or diesel burner. Regular maintenance, as outlined in this guide, will not only extend the life of your burner but also contribute to significant energy savings and peace of mind.

Read more: Evo Oil Sprayer: 5 Must-Have Features

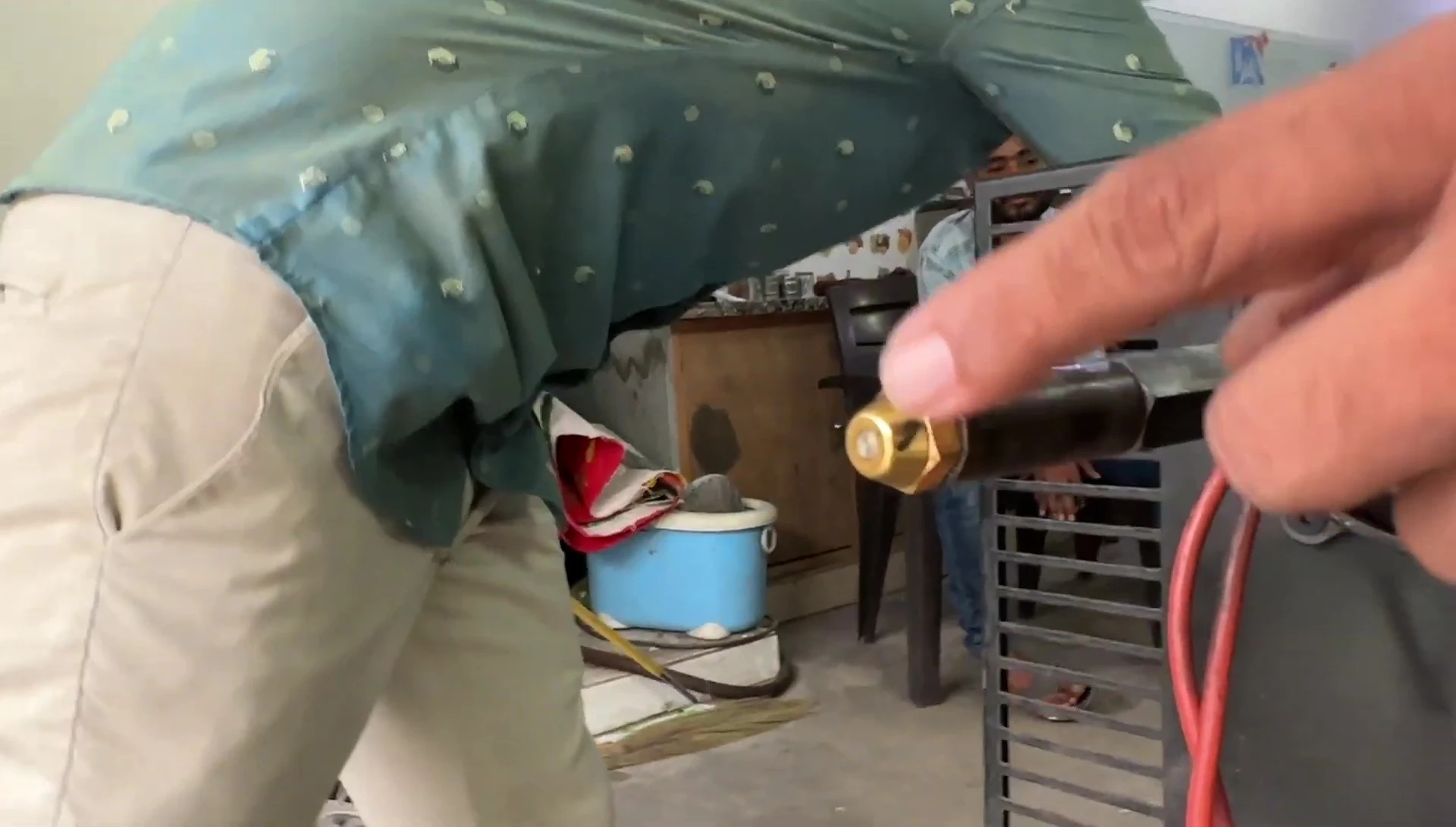

Nozzle Replacement

Replacing the nozzle in your oil/diesel burner is a crucial maintenance task. It's essential for ensuring optimal combustion and preventing potential issues. Regular nozzle replacement prevents fuel inefficiency and improves the burner's overall performance.

To access the nozzle, locate and remove the bolts on both the left and right sides of the burner. Gently pull out the nozzle assembly. Before proceeding to replace it, you'll need to disconnect the ignition controller.

The nozzle itself can become clogged or worn, impacting the spray pattern and fuel efficiency. Careful removal and replacement are key to restoring optimal performance. Remember to follow the instructions carefully and ensure proper reassembly for safe operation.

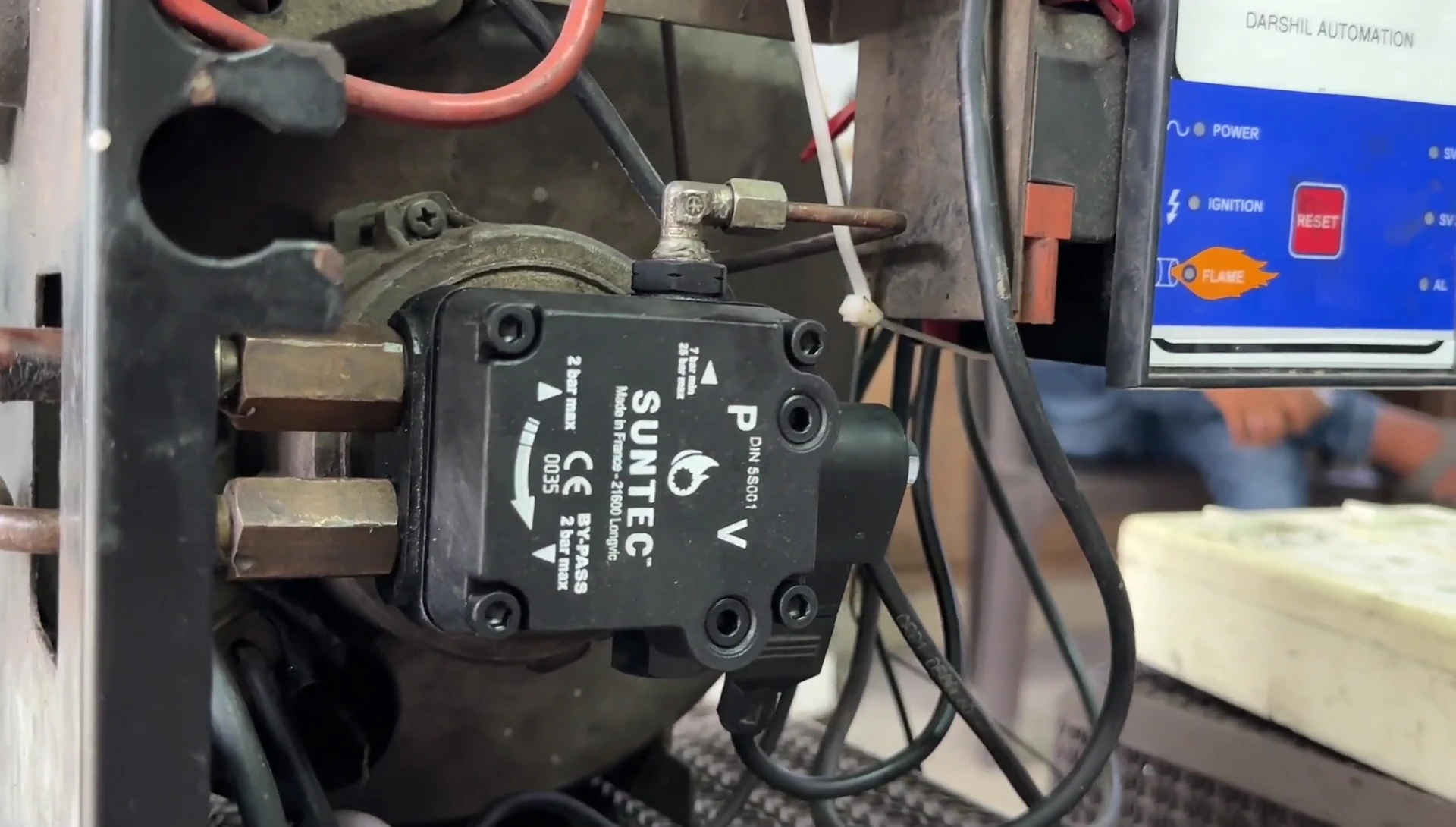

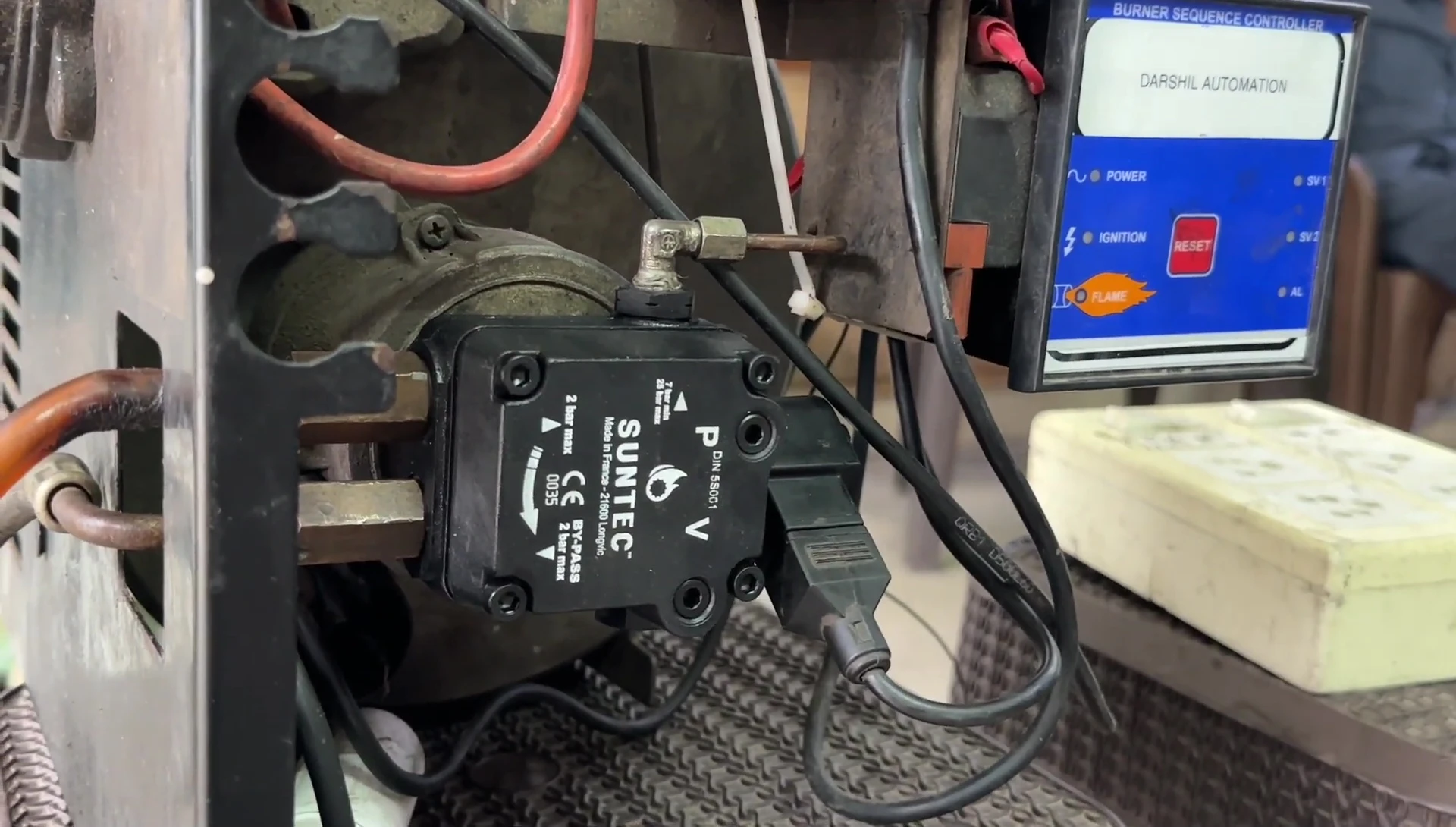

Diesel Pump Replacement

The diesel pump is the heart of your burner. A faulty pump can lead to inadequate fuel delivery and burner failure. Regular inspection and replacement, if necessary, are crucial for maintaining the efficiency and longevity of your system.

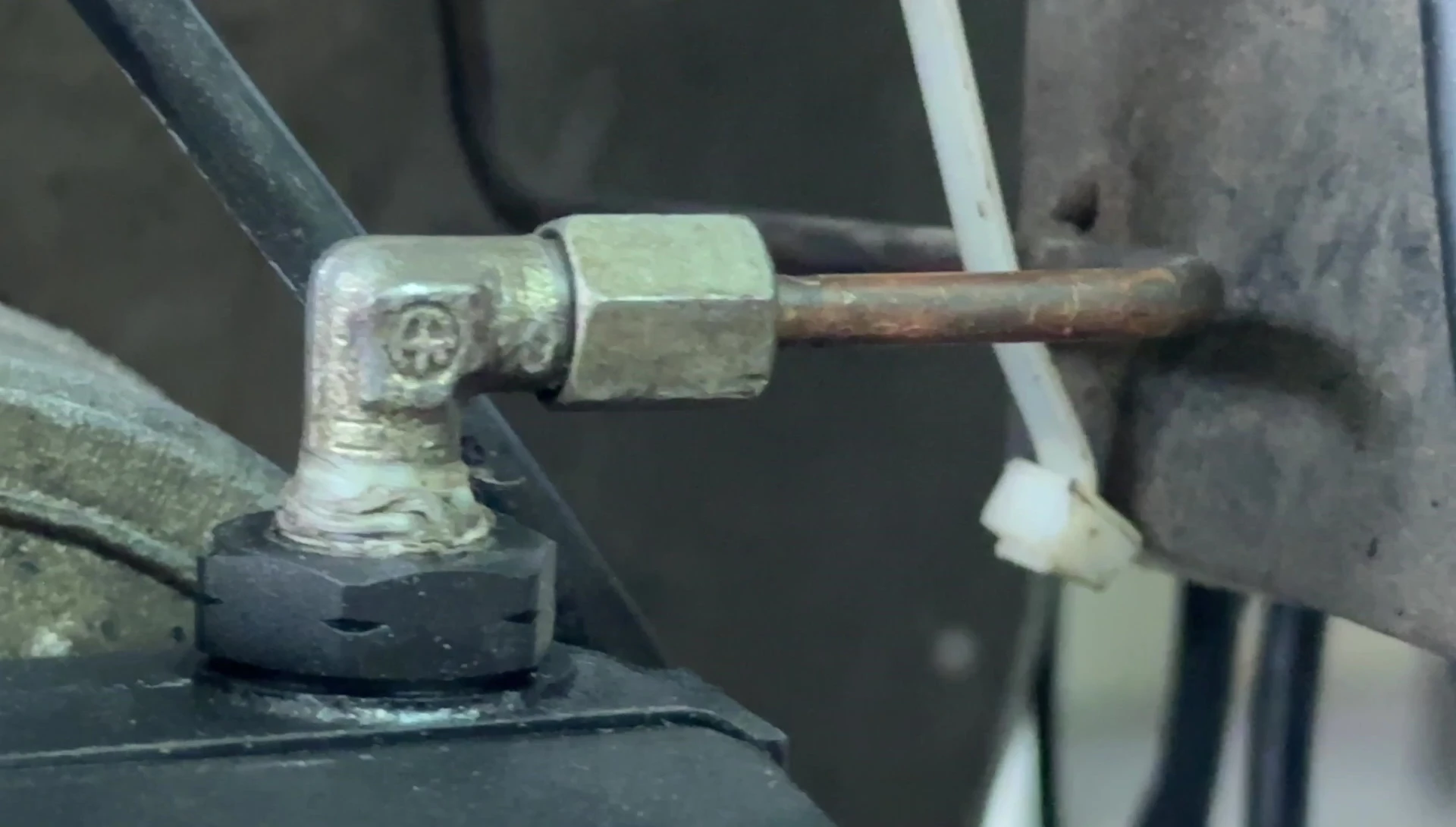

To replace the pump, begin by disconnecting the inlet, return, and outlet lines. Carefully remove the pump from the oil tank by unscrewing the securing nuts and bolts. Then install the new pump, ensuring all connections are secure and leak-free.

Always use a pump that matches the specifications of your burner. Proper installation ensures safe and efficient fuel delivery. After replacement, check the pressure for proper operation to confirm a successful installation.

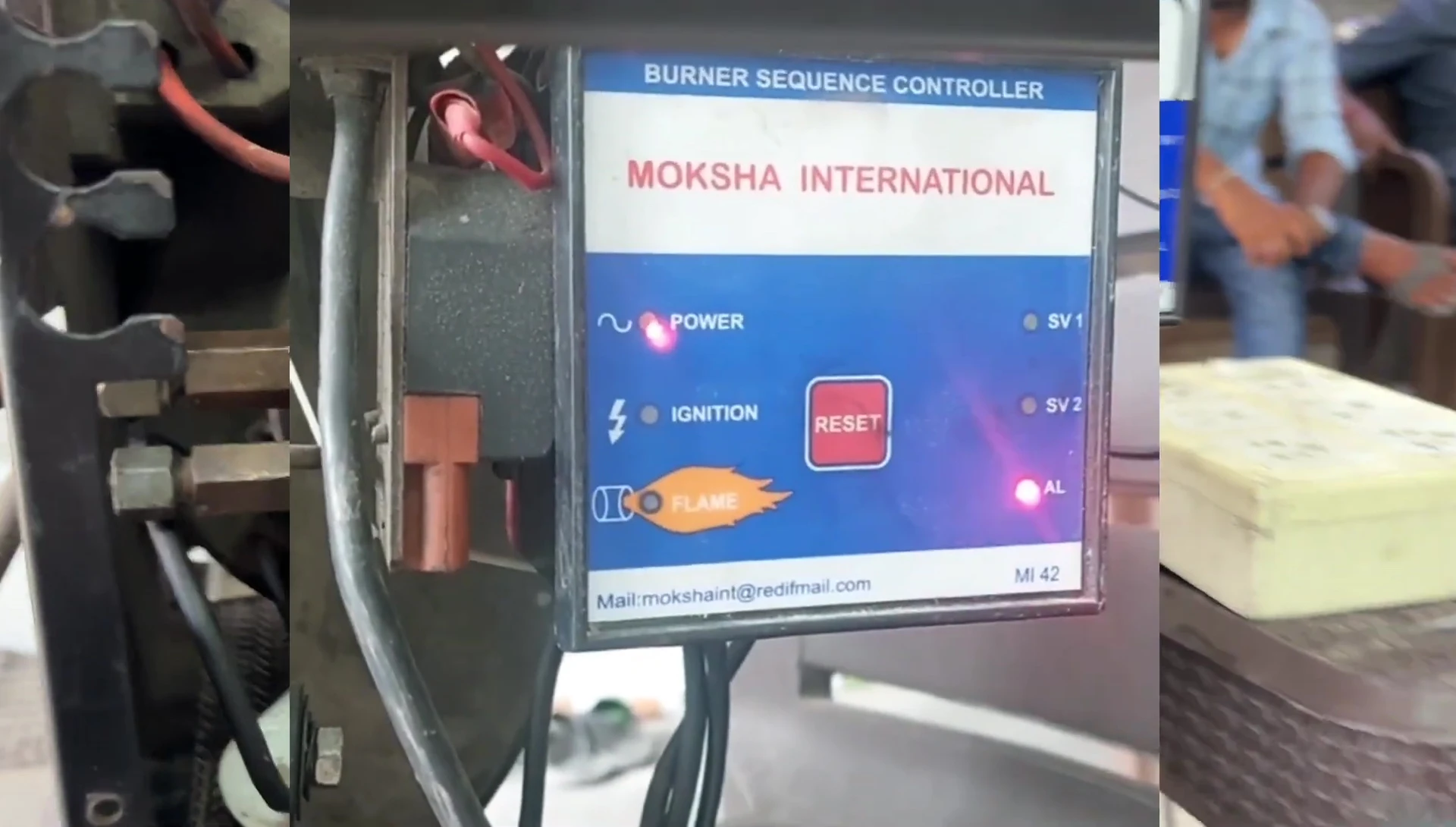

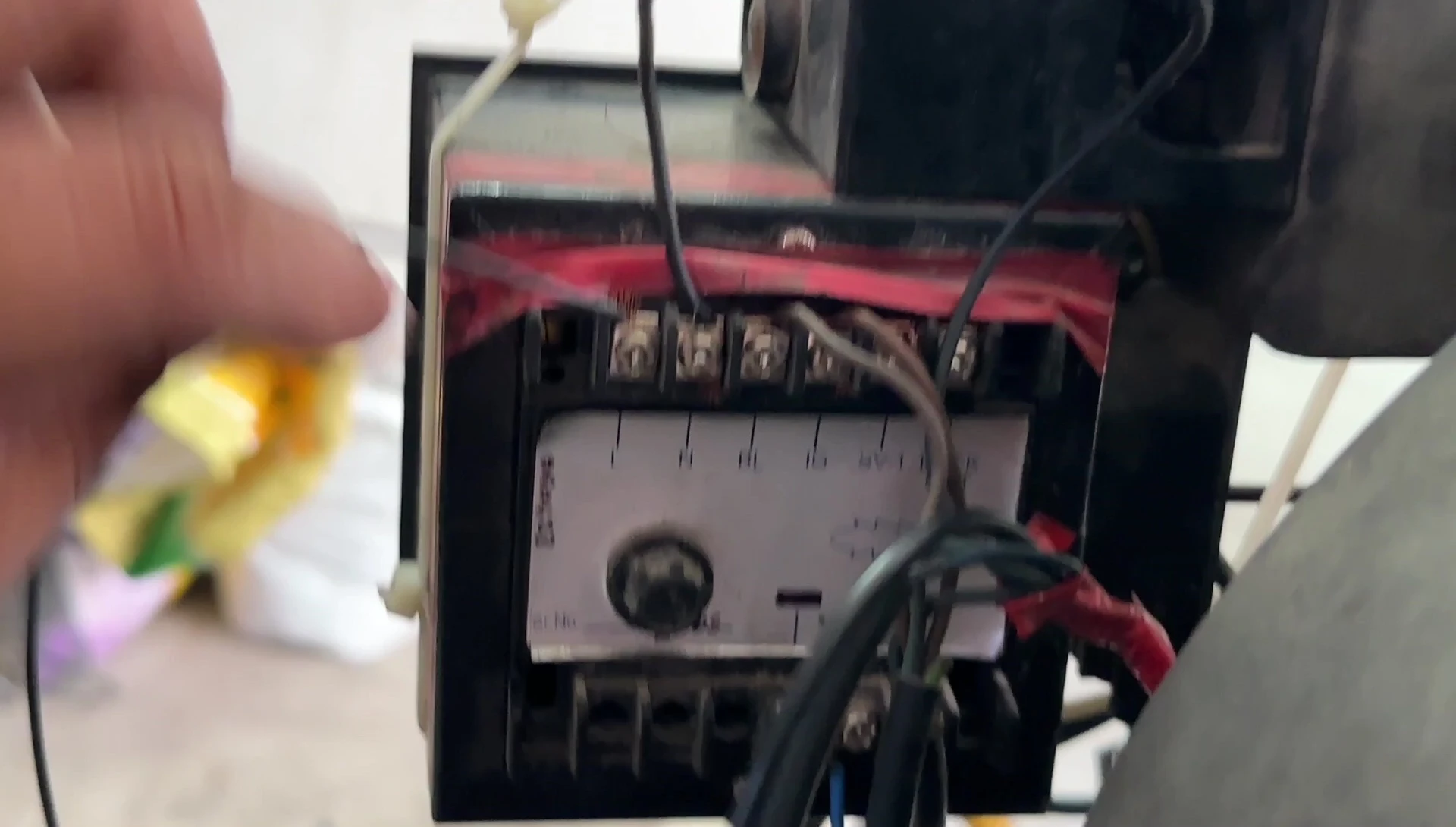

Understanding the Sequence Controller

The sequence controller manages the entire operation of the burner. Understanding its function is crucial for troubleshooting and maintenance. This includes the blower, pump, ignition, and safety features.

The controller ensures that the blower and pump start simultaneously, followed by ignition after a brief delay. A crucial component is the light sensor (LDR), which monitors the flame and triggers an alarm if there's a failure to ignite.

Proper functioning of the sequence controller ensures a safe and efficient burning process. Any malfunction needs immediate attention to prevent potential hazards. Regular inspection and maintenance of the controller is key.

Wiring and Practical Trial

The wiring of the oil/diesel burner is relatively straightforward. Understanding the connections is essential for maintenance and repairs. Ensure proper connections to avoid electrical hazards.

Key components in the wiring include the power supply, blower motor, diesel pump, ignition system, and the safety sensor. Each component needs a dedicated wire connection to the sequence controller.

Always disconnect power before any wiring work. Incorrect wiring can lead to malfunctions or safety hazards. Refer to the wiring diagram for proper connections and troubleshooting

Conclusion

Maintaining your oil/diesel burner involves regular checks and occasional replacements of components such as the nozzle and pump. These tasks are crucial for optimal performance, safety and longevity.

Understanding the sequence controller and wiring is vital for troubleshooting and maintaining the burner's functionality. Regular maintenance, along with prompt attention to any issues that arise, keeps your oil/diesel burner running smoothly.

This guide provides a comprehensive overview of common issues and maintenance procedures for oil/diesel burners. By performing routine maintenance, you can extend the lifespan of your burner and ensure efficient and safe operation.