This article delves into the fascinating world of powerful tree shredders and wood chippers, exploring a range of machines that redefine efficiency and power in timber processing and waste management. From the awe-inspiring might of Timbertime's wood chipper to the precision of automated sawmill technology, we showcase a diverse collection of industrial and consumer-grade equipment. We examine both the raw power and controlled precision involved in transforming raw materials into usable products, highlighting the technological advancements shaping modern forestry and recycling practices.Prepare to witness the breathtaking capabilities of these machines, from high-speed log splitters and whole-tree processors to innovative scrap wood shredders and efficient branch chippers. We'll explore the environmental impact, the advancements in automation, and the sheer destructive (yet constructive) power of these tools, offering a glimpse into the future of sustainable timber processing and waste reduction. This deep dive will showcase the impressive engineering and technological marvels behind these powerful machines.

Pros And Cons

- Separates wood chips with high-frequency precision

- Clean output, zero waste

- Processes 8 to 12 cubic meters/hour

- Automatic cutting and splitting

- What used to take three people all day now takes one person an hour

- Grips, feeds, and mills with flawless control

- Turns logs into perfect beams quickly and smoothly

- Handles peeling, gluing, and pressing

- Stunning precision and zero wasted motion

- Turns raw timber into polished panels in one smooth loop

Read more: 10 Best Commercial Charcoal Grills: A Buyer's Guide

The Brutal Efficiency of Timbertime

Timbertime's wood chipper and shredder are not for the faint of heart. The sheer power and destructive capability are captivating, transforming massive logs and stumps into manageable chips with frightening efficiency. Witnessing this machine in action is a visceral experience, a blend of awe and controlled chaos.

The machine's raw power is amplified by the Peterbuilt engine, a testament to the combination of robust engineering and impressive horsepower. The process is brutal, loud, yet strangely addictive to watch. The final result, a mountain of wood chips, speaks volumes about its effectiveness.

BW16-D: The Game-Changing Log Splitter

The BW16-D log splitter isn't just a tool; it's a game-changer. With a staggering 20 tons of force and a four-way wedge, it processes logs at an incredible rate, reaching up to 1.5 cords per hour with a remarkably fast 6-second cycle time. The efficiency is astounding, eliminating jams and waste for consistently clean splits.

This machine represents a significant advancement in wood processing technology. The speed and precision are remarkable, showcasing a level of automation rarely seen in traditional wood-splitting operations. The clean cuts and high output are a testament to its superior design and engineering.

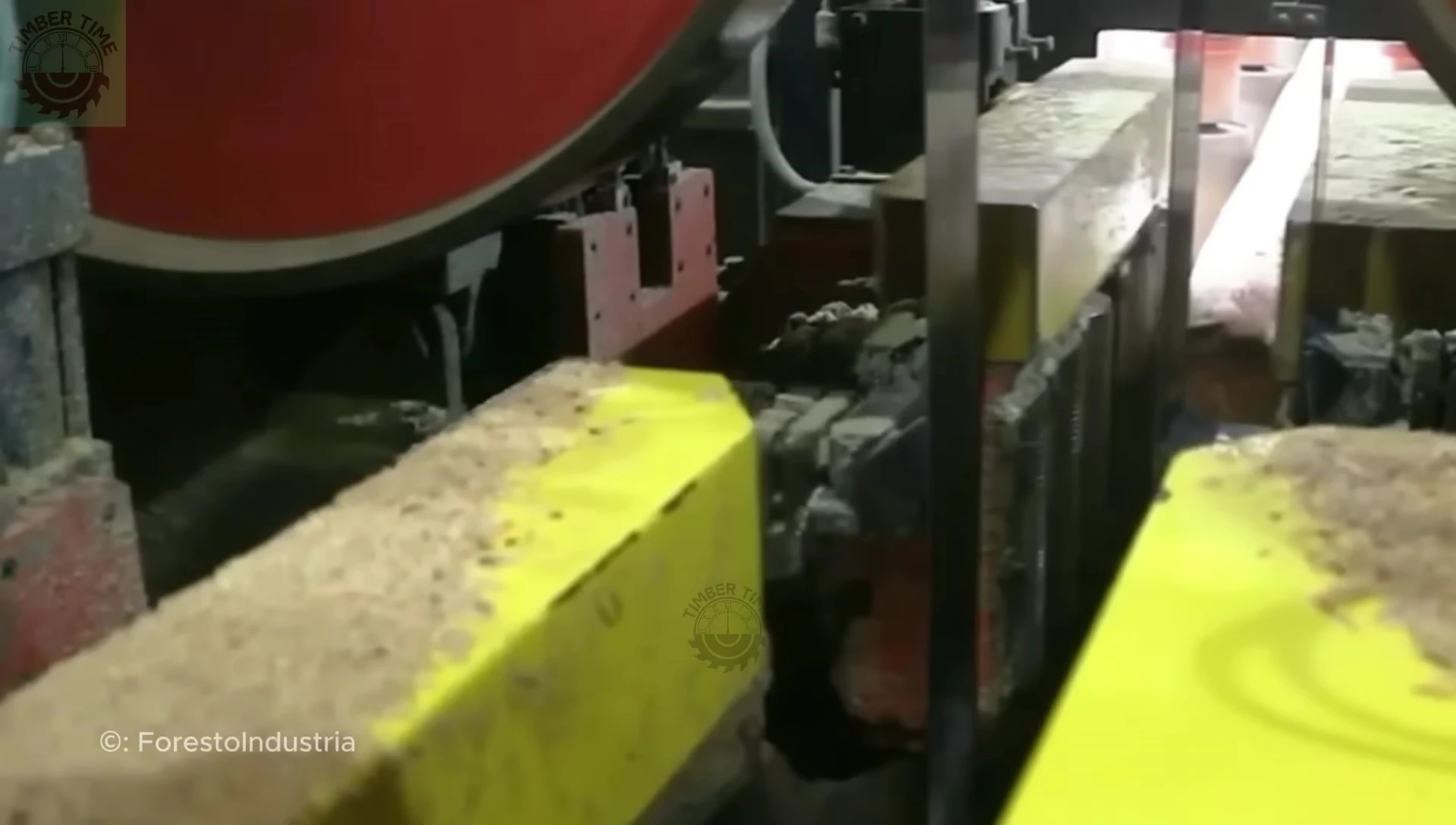

Modern Sawmill Technology: Precision and Automation

Modern sawmill technology has revolutionized the timber industry. These advanced sawmills utilize scanning technology to precisely center and slice logs, turning raw timber into flawlessly dimensioned beams in mere seconds. The level of automation is astonishing, minimizing human intervention.

This high level of precision and automation not only increases efficiency but also improves the quality of the finished product. The reduced human input suggests a future where fully automated lumber production is a reality. The speed and accuracy raise questions about the future of traditional woodworking techniques.

Viber 84 Hugo Combo: A Logging Legend

The Viber 84 Hugo Combo is a powerhouse, handling 80cm logs with ease. It processes logs incredibly fast, producing chips in mere seconds. This machine exemplifies modern logging excellence, representing a significant advancement in efficiency and output.

The sheer speed and power displayed are breathtaking. The machine’s ability to handle large logs so quickly and efficiently highlights its superior design and robust construction. It’s clear that this machine sets a new standard for modern logging operations.

Efficient Waste Reduction with Wood Shredders

The showcased wood shredder offers an innovative solution to waste management. Using slow-speed, high-torque augers, it efficiently crushes bulky scrap wood with minimal noise and clogging. This quiet power is a testament to thoughtful engineering and optimized design.

This machine demonstrates a commitment to sustainability. The ability to process large volumes of scrap wood quietly and efficiently reduces waste and minimizes environmental impact. Its quiet operation is a particularly notable aspect, differentiating it from noisier alternatives.

Cubic 2013 Firewood Processor: Streamlined Firewood Production

The Cubic 2013 firewood processor significantly boosts productivity. With automatic cutting and splitting capabilities, it processes 8-12 cubic meters of wood per hour, requiring only one person to operate the machine. This machine effectively transforms manual labor into a highly efficient, automated process.

This significant reduction in labor costs and time is a game-changer for firewood production. The Cubic 2013’s automated features make it a valuable asset for businesses and individuals alike. Its high throughput and single-person operation make it stand out amongst traditional methods.

Scanning Saw Line: The Future of Timber Processing

The scanning saw line exemplifies the future of woodworking. It utilizes real-time log shape detection to adjust blades automatically, producing clean cuts in seconds. This system offers unparalleled precision and speed, transforming rough timber into smooth boards with astonishing efficiency.

The precision and speed of this system are truly remarkable. The seamless integration of technology and woodworking demonstrates the potential for highly automated, efficient timber processing. The nearly flawless results speak for themselves, establishing a new standard of quality.

Coupe Eco Meteor P270: Safe and Efficient Branch Shredding

The Coupe Eco Meteor P270 is a safe and efficient solution for branch shredding. Its telescopic arm allows for high-canopy access without climbing, minimizing risk. The machine’s circular blade, spinning at 2,000 RPM, easily shreds thick branches.

This machine prioritizes both efficiency and safety. The combination of a powerful shredding mechanism and a telescopic arm makes it particularly suitable for steep terrain, improving worker safety significantly. The reduction in fuel consumption further enhances its economic advantages.

Compact Wood Shredder: Transforming Chaos into Clean Ground

This compact wood shredder is incredibly efficient, reducing full-grown saplings to mulch in seconds. Its size belies its power, transforming large volumes of material quickly and efficiently.

The compact design makes this shredder incredibly versatile. The speed and efficiency of the process are striking, offering a convenient solution for waste management. Its compact size allows for easy maneuverability in tight spaces, adding to its practical appeal.

Hydraulic Press: A Mechanical Ballet of Force

The hydraulic press showcases raw, controlled power. It crushes vehicles with brutal precision, transforming them into compressed metal in a mesmerizing display of force. The process is both captivating and slightly unsettling.

This machine demonstrates the incredible power of hydraulics. The controlled precision of the crushing process is impressive, highlighting the machine’s ability to precisely control immense force. The rapid compression and final result leave a powerful visual impression.

Elite Super Prof Shredder: Branch Reduction Made Easy

The Elite Super Prof Shredder is a powerful tool for branch reduction. Its 18-horsepower engine easily handles limbs up to 60 mm thick, turning hours of work into a task completed in under an hour. The shredder's efficiency is remarkable, making quick work of substantial quantities of branches.

This shredder offers a considerable advantage in terms of time and effort. The powerful engine ensures efficient processing, turning a time-consuming task into a manageable one. The machine's capacity to handle thick branches without difficulty further emphasizes its superior design and performance.

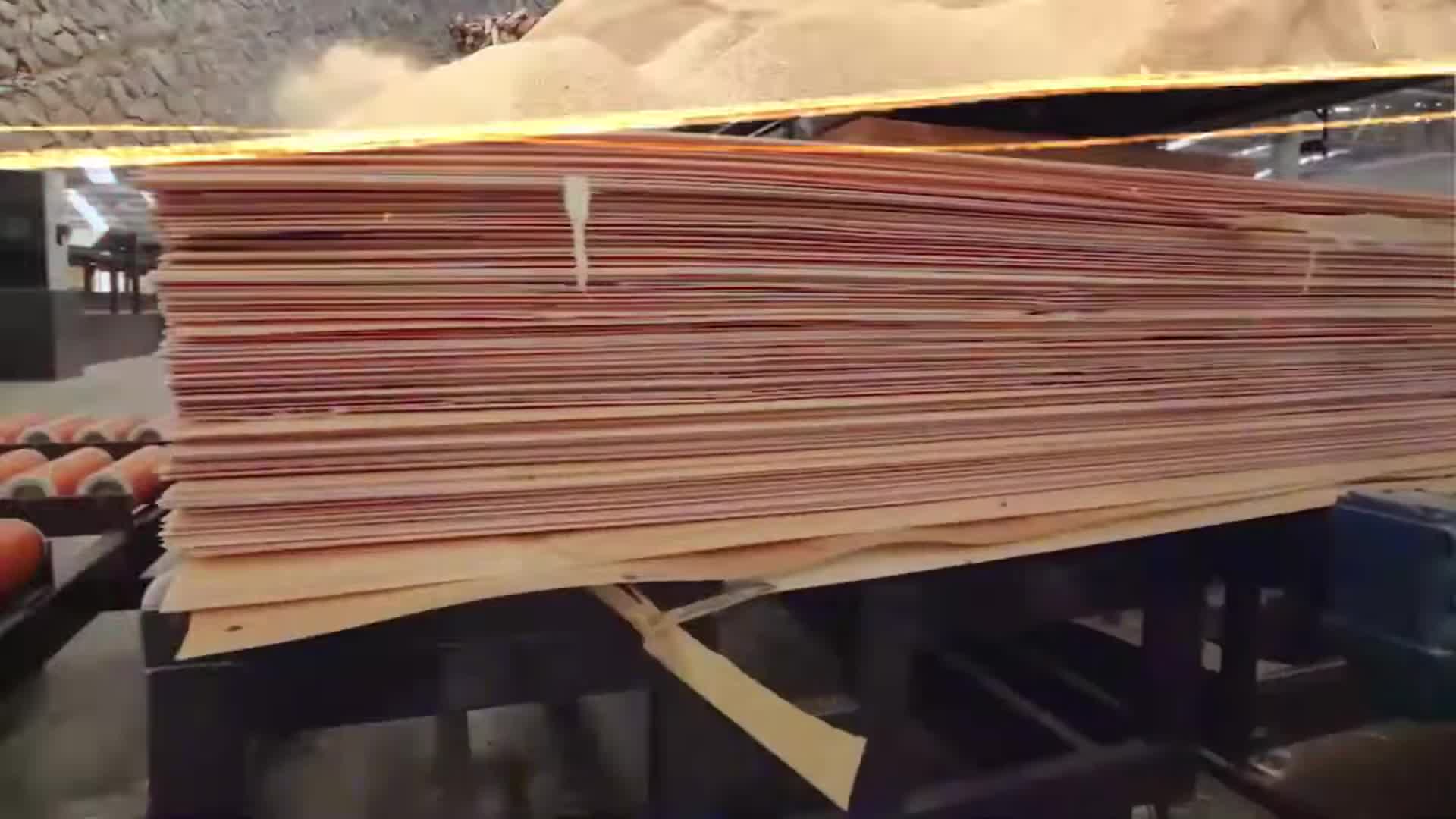

High-Speed Plywood Press Line: From Log to Panel with Stunning Precision

This high-speed press line transforms raw logs into polished plywood with stunning speed and precision. The entire process, from peeling and gluing to pressing, is seamless and efficient, highlighting the advancements in automated manufacturing.

This automated process represents a significant leap forward in plywood production. The speed, precision, and efficiency of the entire line showcase the power of automation. The polished panels are a testament to the system’s ability to produce consistent, high-quality results.

Crushing Yard: Raw Transformation and Recycling

The crushing yard showcases the power of industrial recycling. The loader stacks vehicles like toys, with the press then swiftly crushing them. This process effectively transforms waste into recyclable materials. The scenes are both powerful and thought-provoking.

This intense process highlights the scale of industrial recycling. The efficiency of the process demonstrates the potential for reducing waste and recovering valuable materials. The rapid destruction also raises important considerations about resource management and environmental responsibility.

Homemade Wood Splitter: DIY Genius

This homemade wood splitter is a marvel of ingenuity. Its 24-way wedge swiftly slices logs into firewood, demonstrating the power of simple, effective design. This remarkable creation showcases resourcefulness and a deep understanding of mechanics.

The ingenuity and efficiency of this DIY project are remarkable. The 24-way wedge and rotating drum offer a surprisingly effective method of firewood production. The design's simplicity highlights the potential for creative solutions in woodworking.

Precision Hedge Trimming with a Rotating Tool

This precision hedge trimming tool offers exceptional control and speed. Its smooth rotation and clean cuts make it ideal for detailed work. The machine's efficiency and precision are remarkable, resulting in beautifully manicured hedges.

The tool's ability to create clean cuts and maintain a smooth rotation speaks to its superior design and build quality. Its efficiency and precision make it a standout solution for meticulous hedge trimming. The results are visually stunning, showcasing a level of artistry rarely seen in hedge trimming.

Miore F1 Vertical Band System: High-Volume, High-Quality Timber Production

The Miore F1 vertical band system represents the pinnacle of high-volume, high-quality timber production. Its powerful carriage and motor enable it to slice beams with millimeter accuracy at impressive speeds. The machine's efficiency and precision are truly remarkable.

This system showcases the future of timber processing. Its high-speed, high-precision capabilities suggest a future where large-scale timber operations are both efficient and produce exceptionally high-quality materials. The results speak to the transformative potential of modern technology in woodworking.

Vector 4S Cross Country Shredder: Off-Road Branch Crushing

The Vector 4S cross-country shredder is designed for rugged terrain. Its track drive and powerful engine allow it to crush branches with ease, even in difficult conditions. The machine's versatility makes it ideal for various outdoor applications.

The Vector 4S’s off-road capabilities set it apart. Its ability to function effectively in challenging environments expands its usefulness considerably. Its power and efficiency make it a valuable asset for managing branches in remote or difficult-to-access locations.

Green Tech 1445: Whole Tree Processing

The Green Tech 1445 prototype is a groundbreaking machine that devours whole trees with ease. Its large feed capacity and direct chip loading system make it incredibly efficient. This revolutionary machine suggests a future where whole-tree processing becomes the industry standard.

This machine represents a major step forward in sustainable forestry practices. Its ability to process whole trees efficiently minimizes waste and reduces the need for multiple processing steps. The potential environmental benefits are significant, highlighting a commitment to sustainable logging techniques.

Industrial Crusher: Recycling and Environmental Responsibility

The industrial crusher highlights the importance of responsible recycling. While crushing vehicles is a powerful visual display, it also represents a crucial step toward reducing waste and metal pollution. This process contributes to a more sustainable future.

The industrial crusher demonstrates that destruction can be constructive. The process reduces landfill space and recovers valuable steel, improving resource management and minimizing environmental impact. However, the sheer scale of waste production also emphasizes the importance of preventative measures and further improvements in recycling technology.

Heavy Machinery in Stone Crushing: Efficiency vs. Environmental Impact

The use of bulldozers and breakers in stone crushing is visually impressive, highlighting the scale of the operation. The efficiency is undeniable, but the dust clouds and noise raise concerns about environmental impact.

The sheer power of the machinery is impressive, but it’s crucial to consider the environmental impact. The dust and noise pollution raise important questions about sustainable practices in the construction and mining industries. Balancing efficiency with environmental responsibility is critical for future operations.

Backyard Garden Grinder: Efficient Garden Waste Management

This backyard garden grinder is a powerful yet convenient tool for managing garden waste. It rapidly shreds branches into mulch, making it a valuable asset for any gardener. The machine's efficiency makes a significant impact on cleanup time and waste management.

This tool offers an efficient and effective solution for garden waste disposal. The rapid shredding capabilities reduce the amount of time and effort needed for cleaning up garden debris. Its convenience and ease of use are significant advantages for home gardeners.

Industrial Shredder: Raw Power and Shearing Force

This industrial shredder uses a sophisticated system of interlocking blades to create immense torque. Objects are trapped, twisted, and sheared with incredible force, demonstrating the power of opposing forces. The machine's design is a testament to effective engineering.

The industrial shredder showcases the potential for controlled destruction. The system's ability to efficiently and effectively process large volumes of material is impressive. The interlocking blades and opposing angles create a remarkably effective shredding mechanism.

Valtra with Serat Bio Green Grinder: Stump Shredding Powerhouse

The Valtra paired with a Serat Bio Green grinder is a powerful combination for stump removal. With its substantial horsepower, it quickly transforms rugged terrain into mulch. This pairing demonstrates the synergy between powerful machinery and effective attachments.

The combined power of the Valtra and the Serat Bio Green grinder is remarkable. The efficiency of the stump-shredding process is impressive, transforming large stumps into manageable mulch in a short period of time. The combination of tractor and grinder demonstrates the practicality and effectiveness of specialized attachments for large-scale land management.

Vibrating Screener: Efficient Wood Chip Separation

This vibrating screener uses high-frequency precision to separate wood chips. Its efficient design ensures clean output and minimal waste. This machine highlights the importance of advanced technology in optimizing resource utilization.

The efficiency and precision of the vibrating screener are remarkable. The minimal waste generated is a testament to its effective design. The process showcases how advanced technology can improve the efficiency of resource management in various industries.

Volvo MC T110C with Brush Cutter: Efficient Land Clearing

The Volvo MC T110C, paired with a heavy-duty brush cutter, is a formidable land-clearing machine. Its power and lift capacity make quick work of dense overgrowth. The machine is incredibly effective for clearing large areas efficiently.

The combination of the Volvo excavator and the brush cutter is a powerful force in land clearing. The machine's ability to efficiently clear dense overgrowth makes it ideal for large-scale land management projects. Its high horsepower and lift capacity are significant contributors to its effectiveness.